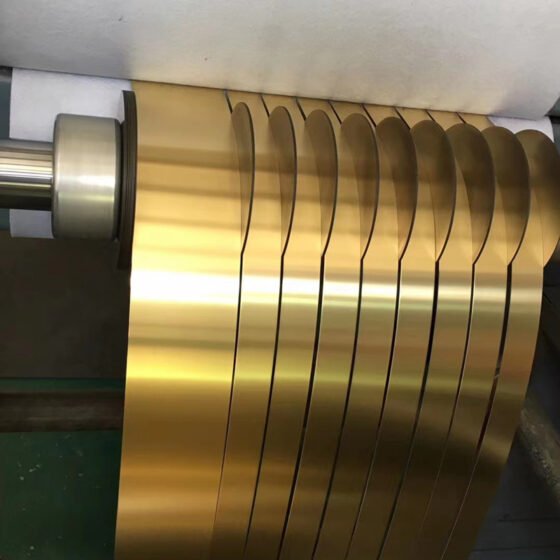

The Brass Bar Rod H80 C24000 Flat Bar is a high-quality brass alloy composed of copper and zinc, with a copper content of approximately 80%. Known for its strength, excellent corrosion resistance, と汎用性, this material is ideal for use in various industrial and architectural applications. With a higher copper content, it exhibits superior machinability and durability compared to other brass alloys. This flat bar is widely used in the manufacture of components that require high strength, good electrical conductivity, and aesthetic appeal.

特徴:

- High Copper Content: With approximately 80% copper, the alloy offers excellent corrosion resistance, high conductivity, and durability.

- Good Machinability: The material is easy to machine, making it suitable for creating precision parts with intricate designs.

- 耐食性: Its copper-rich composition ensures that it resists oxidation and corrosion, making it suitable for harsh environmental conditions.

- Durable: Strong and tough, the material can withstand mechanical stress and wear, ensuring long service life.

- Aesthetic Appeal: The golden-yellow appearance of brass makes it a popular choice for decorative and architectural applications.

- Versatile Use: Ideal for both functional and decorative applications due to its strength, machinability, and appearance.

アプリケーション:

- Precision Machining: Commonly used in the production of precision parts, such as gears, shafts, and fasteners, that require high machinability and strength.

- Architectural Applications: Frequently used for decorative trim, handles, door hardware, and other architectural elements where both function and appearance matter.

- Electrical Components: The high copper content makes it ideal for manufacturing electrical connectors, terminals, and other components requiring good conductivity.

- Plumbing Fittings: Used in creating durable plumbing parts like faucets, valves, and connectors, where corrosion resistance is important.

- Marine Industry: Ideal for use in marine equipment and fittings, as it resists the corrosive effects of saltwater environments.

- Automotive Parts: Utilized in automotive parts that require corrosion resistance, such as connectors, fittings, and small engine components.

1. どのような種類の材料を提供していますか?

私たちは高品質の銅の供給を専門としています (純銅と合金を含む), アルミニウム (さまざまなグレードと形式で), と真鍮材料. 当社の製品範囲にはシートが含まれます, プレート, コイル, 棒, チューブ, およびカスタムソリューション.

2. カスタマイズされたサイズと仕様を提供できますか?

はい, 私たちはあなたの特定の要件を満たすためにカスタマイズされたソリューションを提供します. カスタムディメンションかどうか, 厚さ, または仕上げ, 私たちはあなたのニーズに合わせて私たちの製品を調整することができます.

3. あなたの材料はどの業界に貢献していますか?

当社の材料は、建設などの業界で広く使用されています, 自動車, 電気的な, 配管, 空調, 包装, および装飾的な用途.

4. 国際規格に準拠していますか?

はい, 当社のすべての製品は、ASTMなどの国際規格に適合しています, 日本語, および GB/T. 私たちは、すべての製品に最高の品質と信頼性を保証します.

5. 最小注文数量はいくつですか (最低発注書)?

当社のMOQは、材料と製品の種類によって異なります. お客様の特定の注文要件については、直接お問い合わせください.

6. サンプル資料はありますか??

はい, 評価用のサンプルを提供できます. サンプルの詳細についてはお問い合わせください, サイズと配送手配を含む.

7. 製品の品質をどのように確保しますか?

信頼できるメーカーから材料を調達し、生産の各段階で厳格な品質管理チェックを実施しています. 各製品は、お客様の仕様を満たしていることを確認するために検査されます.

8. 配送オプションは何ですか?

柔軟な配送オプションを提供しています, 海を含む, 空気, そして陸上輸送, 迅速で信頼性の高い配送を確保するため. また、輸出書類や通関手続きにも対応しています.

9. 海外への発送は可能ですか??

はい, 私たちは世界中のクライアントに輸出しています, アジアの地域を含む, ヨーロッパ, 南北アメリカ, そしてその先へ.

10. 見積もりを取得するにはどうすればよいですか?

メールまたは電話で直接お問い合わせください, または、当社ホームページのお問い合わせフォームにご記入ください. 材料の種類についての詳細をお知らせください, 寸法, 量, 正確な見積もりのための配送場所.

11. どのような支払い方法が利用できますか?

さまざまなお支払い方法をご利用いただけます, T / Tを含む (銀行振込), L/C(L/C), およびその他の安全なオプション. 支払い条件は、注文プロセス中に話し合うことができます.

12. リードタイムはどのくらいですか?

リードタイムは製品と数量によって異なります. 通常, 注文は 7-15 日, ただし、お客様の要件に基づいて正確なタイムラインを確認します.

13. 材料認証を提供できますか?

はい, 材料認証を提供できます, ミルテスト証明書を含む (MTCの) およびその他の必要な書類, はお問い合わせください.

14. サポートチームに連絡するにはどうすればよいですか?

お問い合わせページからお問い合わせください, 電子メール, または電話. 私たちのチームは、あなたが必要とするどんなお問い合わせやサポートでもあなたを助ける準備ができています.

1. 高品質の素材

私たちはプレミアム銅の供給を専門としています, アルミニウム, ASTMなどの国際規格を満たす真鍮材料, 日本語, および GB/T. 当社の製品は、信頼性を確保するために信頼できるメーカーから供給されています, 耐久性, そして優れたパフォーマンス.

2. 包括的な製品ラインナップ

シートから, プレート, ロッドへのコイル, チューブ, およびカスタムプロファイル, 建設業など業界の多様なニーズにお応えするため、豊富な製品を取り揃えています, 自動車, 電気的な, その他.

3. カスタマイズオプション

私たちは、すべてのプロジェクトがユニークであることを理解しています. だからこそ、私たちはオーダーメイドのソリューションを提供します, カスタムサイズを含む, 厚さ, 仕上げ, および特別な要件, お客様の仕様に正確に合わせるために.

4. 競争力のある価格設定

メーカーとの強力なパートナーシップと合理化されたサプライチェーン運用により、品質を損なうことなく競争力のある価格を提供することができます.

5. 厳格な品質管理

私たちは厳格な品質保証プロセスに従って、すべての製品がお客様の期待に応えるか、それを超えることを確認します. 各注文は、配送前に徹底的な検査を受けます.

6. 効率的なロジスティクス

位置: 無錫, 水が絶え間なく広がる街, 陸, と航空輸送のリンク, 私たちは、世界中のクライアントにタイムリーで信頼性の高い配達を保証します. 海路かどうか, 空気, または土地, お客様のニーズに合わせた効率的な配送ソリューションをご提供します.

7. グローバルリーチ

長年の輸出経験を持つ, 私たちはアジア全域のクライアントにサービスを提供しています, ヨーロッパ, 南北アメリカ, およびその他の地域, 専門的な輸出書類と通関サポートの提供.

8. 専任のカスタマーサービス

私たちのチームは、あらゆる段階で優れたサービスを提供することをお約束します. お問い合わせからお届けまで, 明確なコミュニケーションを確保します, 迅速な対応, そしてシームレスな体験.

9. 長期的なパートナーシップ

私たちは誠実さを大切にします, 信託, そして私たちの関係における信頼性. 私たちの目標は、高品質の製品と優れたサービスを一貫して提供することにより、クライアントとの永続的なパートナーシップを構築することです.

10. 確かな実績

当社の素材は広く認識され、世界中のお客様から温かく歓迎されています. 多くのクライアントがリピートビジネスのために戻ってきます, 私たちが提供する品質と信頼の証です.

ロウィファーメタル

ロウィファーメタル