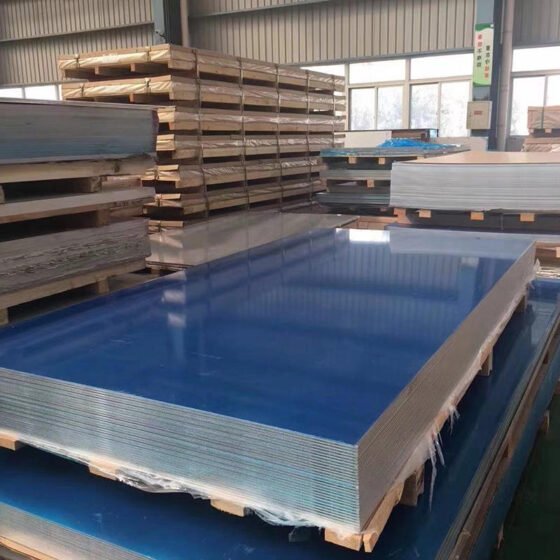

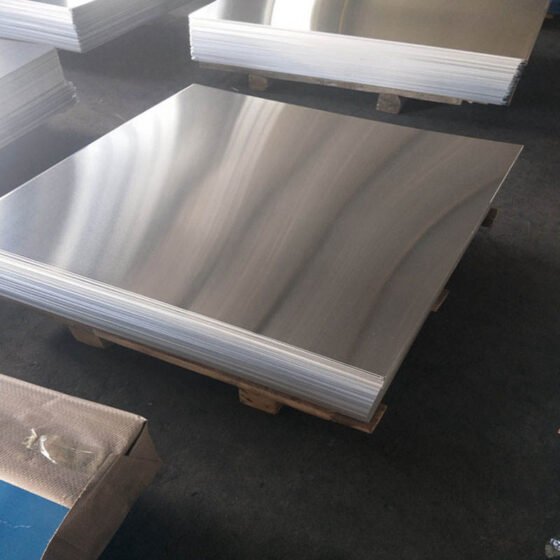

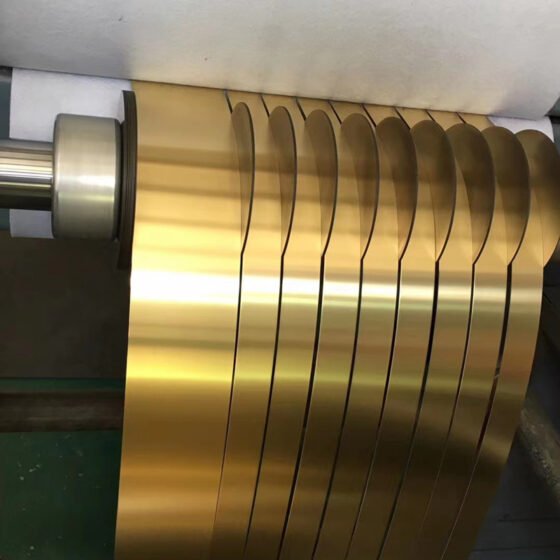

알루미늄 시트/플레이트 7075 T651 is a high-strength, heat-treated alloy primarily composed of zinc, making it one of the strongest aluminum alloys available. It offers excellent strength-to-weight ratio, high fatigue resistance, and is widely used in aerospace, military, and structural applications where high strength and toughness are critical. Due to its superior performance, 7075 T651 aluminum is suitable for demanding environments that require high mechanical properties, resistance to corrosion, and good workability.

주요 기능들:

- Exceptional Strength: One of the strongest aluminum alloys, ideal for high-stress applications.

- High Fatigue Resistance: Performs excellently in applications subjected to repeated stress.

- 내식성: Provides good resistance to atmospheric and marine corrosion.

- Weldability: While not as easy to weld as other alloys, it can be welded with special techniques, maintaining high strength.

- 우수한 가공성: Ideal for precision machining and complex geometries.

응용 프로그램:

- Aerospace: Aircraft frames, wings, fuselages, and structural components requiring extreme strength and lightweight properties.

- Military and Defense: Components for military aircraft, armor, and other high-performance, high-stress applications.

- Sports and Recreational Equipment: High-performance bicycles, golf clubs, and other sporting equipment.

- Transportation: High-strength components in automotive and marine industries.

- Industrial Machinery: Structural parts and tooling for heavy-duty machinery.

Aluminium Alloy Plate: 7075 T651

| Thickness: | 1-600밀리미터 |

| Width: | 100-3000m |

| 길이: | 500-16000밀리미터 |

| Temper: | O, T3, T4, T5, T6, T8, T651, T76, T7651, T7351, T451, T42, T62, T652, T851 etc. |

| 표준: | GB/T3880, GJB1541, GB/N167, JB2053, GJB2662, ASTM B209, ASME SB-209, KO 485, BS EN 573 |

7075 Aluminum Sheet Chemical Composition:

| Alloy | Si | Fe | Cu (입방체) | Mn | Mg | Cr | Zn | Ti | Others | Aluminium min. | |

| Each | Total | ||||||||||

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remainder |

7075 Aluminum Sheet Mechanical Properties:

| 경도, Brinell | 150 | 150 | AA; Typical; 500 g load; 10 mm ball |

| 경도, Knoop | 191 | 191 | Converted from Brinell Hardness Value |

| 경도, Rockwell A | 53.5 | 53.5 | Converted from Brinell Hardness Value |

| 경도, Rockwell B | 87 | 87 | Converted from Brinell Hardness Value |

| 경도, Vickers | 175 | 175 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 572 MPa | 83000 psi | AA; Typical |

| Tensile Yield Strength | 503 MPa | 73000 psi | AA; Typical |

| Elongation at Break | 11 % | 11 % | AA; Typical; 1/16 in. (1.6 밀리미터) Thickness |

| Elongation at Break | 11 % | 11 % | AA; Typical; 1/2 in. (12.7 밀리미터) 직경 |

| Modulus of Elasticity | 71.7 GPa | 10400 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Poisson’s Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 159 MPa | 23000 psi | AA; 500,000,000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 20 MPa-m½ | 18.2 ksi-in½ | K(IC) in S-L Direction |

| Fracture Toughness | 25 MPa-m½ | 22.8 ksi-in½ | K(IC) in T-L Direction |

| Fracture Toughness | 29 MPa-m½ | 26.4 ksi-in½ | K(IC) in L-T Direction |

| Machinability | 70 % | 70 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 26.9 GPa | 3900 ksi | |

| Shear Strength | 331 MPa | 48000 psi | AA; Typical |

LOWIFAR 메탈

LOWIFAR 메탈