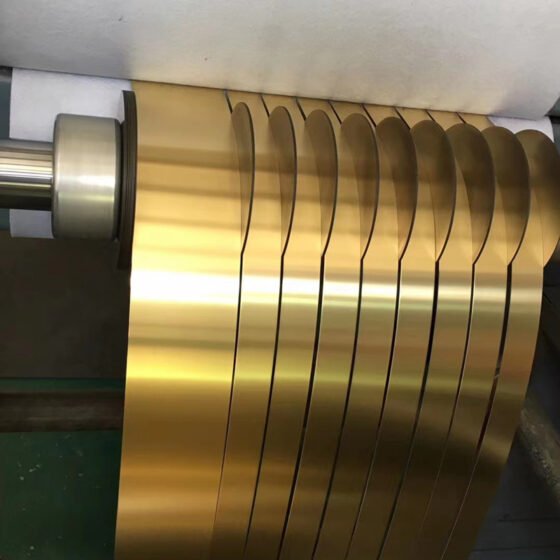

The Brass Bar Rod H63 HPb63-3 C34500 CuZn36Pb3 C3560 Flat Bar is a high-quality brass alloy made up of 36% zinc and 3% lead, with the remaining composition being copper. This material is characterized by excellent machinability, good corrosion resistance, and high strength, making it suitable for various industrial applications. The inclusion of lead in the alloy enhances its machinability, while the copper and zinc combination provides superior durability and resistance to wear and tear. It is commonly used in manufacturing parts that require precision machining and high performance.

Features:

- High Machinability: The inclusion of lead (Pb) in the alloy enhances machinability, allowing for efficient processing and the production of intricate parts with ease.

- Excellent Durability: The combination of copper and zinc ensures the material is resistant to corrosion, making it suitable for use in harsh environments.

- Wear Resistance: Offers high resistance to wear and tear, ideal for components that undergo regular mechanical stress.

- Strength and Toughness: The alloy maintains excellent strength and toughness, even under challenging conditions.

- Versatile Application: Can be used in a variety of applications, from heavy-duty machinery to precision components.

- Aesthetic Appearance: The brass alloy’s golden appearance is often desirable in decorative and architectural applications.

응용 프로그램:

- Precision Machinery: Commonly used in the manufacturing of precision machinery components, gears, and bearings due to its excellent machinability and wear resistance.

- Plumbing and Electrical Fittings: Widely used in the production of plumbing fittings, valves, and electrical connectors where corrosion resistance is crucial.

- Automotive Parts: Utilized in producing automotive components like connectors, fittings, and transmission parts, which require strength and good machinability.

- Architectural Fixtures: Ideal for decorative applications such as hardware, handles, and decorative metal parts due to its attractive golden color.

- Industrial Equipment: Used in the creation of heavy-duty equipment parts that require high strength, wear resistance, and machinability.

- Marine Applications: Its resistance to corrosion makes it suitable for marine equipment and components exposed to water and harsh environments.

| 등급 | ASTM C21000,C22000,C23000,C24000,C26000,C26200,C27000,C27200,28000JIS C2100,C2200,C2300,C2400,C2600,C2620,C2700,C2720,2800 KO |

| Temper | 소프트, 1/4 Hard, 1/2 Hard, Hard, Extra Hard |

| 크기 | 직경: ≤ 500mm

길이: Straight ≤ 12000mm |

| Function & 응용 | With the highest lead content of all the brass alloys, 360 offers the best machine ability. Often called free-machining and free-cutting brass, it stands up to high-speed drilling, milling, and tapping operations with minimal wear on your tools. It’s commonly used for gears, pinions, and lock components. |

| Brass Alloy | Temper | Vickers Hardness (HV) | 인장 강도 (Mpa) | 신장(%) |

| C2800 (H59) | 소프트 | — | ≥320 | ≥35 |

| 1/2H | 105-130 | 410-490 | ≥15 | |

| H | ≥130 | ≥450 | — | |

| C2720 (H63) | 소프트 | ≤90 | ≥295 | ≥45 |

| 1/2H | 105-130 | 370-440 | ≥30 | |

| H | 145-160 | 430-510 | ≥14 | |

| C2680 (H65) | 소프트 | ≤90 | ≥295 | ≥45 |

| 1/2H | 105-130 | 370-440 | ≥30 | |

| H | 145-160 | 430-510 | ≥14 | |

| C2600 (H70) | 소프트 | ≤90 | ≥295 | ≥5 |

| 1/2H | 105-130 | 370-440 | ≥30 | |

| H | 145-160 | 430-510 | ≥14 | |

| C2400 (H80) | 소프트 | ≤80 | ≥255 | ≥44 |

| 1/2H | 100-130 | 320-405 | ≥25 | |

| H | ≥125 | ≥375 | — |

LOWIFAR 메탈

LOWIFAR 메탈